India

has a huge population

of humans and cattle.

One fifth of the population

of earth as well as millions

of cattle reside in India.

So bio-logical waste is

available in abundance.

Unfortunately

no conscientious effort,

except the traditional

use of animal waste as

manure, has been made

to some extent. No effort

has been made to use this

waste for the purpose

of production of energy

to run power plants, vehicles

etc. Several years back

a half hearted effort

was made to use this Bio

- Gas as a source of cooking

with the help of bio-digesters.

This was done by marginal

farmers/cattle breeders

having one or two cattle.

Obviously it did not bring

any worth while response.

Due to the small size

of the plant and improper

handling the out put of

the gas was limited and

irregular. It has always

been considered only as

a stand by alternative

arrangement.

At

no time in the past, an

all out effort to utilise

the potentiality of large

cattle breeders, Gaushallas

and Panjrapols has even

been considered.

By

an approximate formula,

100 cows will give/day

1000/Kg of cow dung, this

in a bio digester will

yield about 40 M3 of Gobar

gas. After removing impurities

such as CO2, Sulphur,

Moisture etc will yield

about 20M3 or 17Kg of

pure methane gas.

It

is only now that, a Technology

has been developed by

us, enabling the use of

this gas from Bio digester.

Gober gas is purified

of all impurities and

moisture. Pure Methane

gas is than Compressed.

This Compressed Bio -

Gas is capable of running

Power plants & Vehicles.

Brief

description & operation

of the plant is as under

This

Project is designed for

-

Bottling Biogas

-

Generating power using

non-conventional energy

-

Driving conventional

vehicles using non-conventional

energy

The

Project has two parts.

Ist part

Deals in separating impurities

such as moisture, Carbon

dioxide and Hydrogen sulfide

and generating pure Methane

from Biogas.

IInd part

Deals in Filtering, compressing

and filling Methane in

a Gas Bottle i.e. a CNG

Dispenser making it suitable

as an IC Engine fuel.

Ist part

Biogas is an economical,

renewable and an eco-friendly

fuel. Biogas is produced

in an anaerobic digester

i.e. a Gobar gas plant.

Biogas in its natural

self consists of Moisture,

Carbon dioxide, Hydrogen

sulfide and Methane gas.

Methane has a high calorific

value in its pure stage.

Due to the presence of

impurities Biogas becomes

a very low calorific value

fuel and hence finds a

very limited application

even though it is cheap

and easily available.

We have to extract pure

and high calorific value

fuel methane from low

calorific fuel Biogas

to make it an IC Engine

suitable fuel. Once pure

Methane is available in

suitable quality and quantity

it finds a wide range

of applications from running

an oil engine, driving

a Motor car Engine to

operating a Gas Turbine

for rural power generation.

Biogas generated from

the digester is allowed

to flow through moisture

traps. This process drains

out the Moisture present

in the gas. The gas is

than allowed to counter

flow in a specially designed

Sulfide extractor. This

filter drains out Balance

Moisture along with the

present sulfides.

Treated gas is pressurized

with the help of a primary

compressor. The filters

mounted drain out any

present moisture and Oil

present post compression.

The pressurized clean

gas is than passed through

a Physical Separation

Device. The Physical Separation

Device is a specially

designed modern high pressure

combined directional flow

device for cleaning Biogas

of it high impurities.

A measuring device is

fitted after the filters

to gauge the quantum of

clean Methane gas collected

in the collecting tank.

IInd

part

This part of our system

now deals in bottling

this clean Methane gas

into a standard CNG bottle.

Gaseous Fuel generates

maximum efficiency when

it is injected into any

CNG converted Internal

combustion Engine with

the desired constant pressure.

The cleaned Methane gas

is than taken into a 3-Stage

high-pressure compressor.

The compressor compresses

the gas from

a) Atmospheric to 10Kg/cm2

in stage I

b) 10Kg/cm2 to 60Kg/cm2

in stage II

c) 60Kg/cm2 to 250Kg/cm2

in stage III

This pressure is considered

suitable to fill up a

CNG bottle rack. This

CNG Bottle Rack can than

be connected to a standard

CNG Dispenser unit. Now

this purified Gobar gas

is ready to be used as

Fuel in a motor car, or

run a Gas Turbine or any

CNG converted Internal

combustion engine connected

to an alternator to produce

electricity.

We

have renamed this Purified

Biogas as CBG - COMPRESSED

BIOGAS.

The

whole System from Input

of Biogas into the Machine

till Filling CBG into

a Vehicle or Bottles consumes

less than 5Kva of Power

for a system designed

to treat 200 M3. of gobar-gas.

Our

system aims on reducing

Capital cost, Operational

costs and space requirements.

The system can safely

be operated by our rural

citizens with minimum

training. Our system has

been designed keeping

Indian rural conditions

in mind. It is so flexible

that it can be mounted

on a Tractor Trolley (if

required), the most common

utility vehicle in all

rural areas.

Due to this, mobile CBG

unit, can cater to more

than one Biogas plant

in a rural area, as some

times due to local conditions,

it may not be possible

to have all the Bio-waste

Digesters in one area.

The Trolley mounted machine

with the help of a tractor

can be transported to

the Bio Digester which

is filled up with the

unrefined gas. The machine

after refining the CBG

can fill up the bottles

which can be stored or

transported to the required

place with ease, causing

an uninterrupted supply

of high calorific value

CBG gas.

A properly coordinated

movement could result

in complete conversion

of Vehicles from fossil-based

fuel to abundantly available

Methane. This movement

would change the face

of Indian economy forever.

The size & cost of

the plant depends upon

the total quantum of Gobar

available.

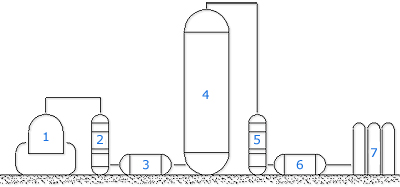

A line diagram explaining

the entire process is

attached.

BIO

GAS PURIFICATION

AND BOTTLING UNIT

LAYOUT DRAWING |

|

| |

|

1.

GOBAR GAS PLANT

2.1ST STAGE PURIFICATION

3.PRIMARY COMPRESSION

4.PHYSICAL SEPERATION |

5.

3RD STAGE PURIFICATION

6. SECONDARY COMPRESSION

7. BOTTLING RACK |

|